You might be surprised to learn how innovative gearbox designs are transforming the automotive landscape in the 21st century. By utilizing advanced materials and smart technologies, these designs not only enhance performance but also improve efficiency and adaptability in various applications, particularly electric vehicles. As we explore the evolution of gearbox technology, consider how these advancements impact your understanding of performance and durability. What implications could these changes have for the future of transportation? The answers may challenge your perspectives on engineering and sustainability.

Evolution of Gearbox Technology

How has gearbox technology transformed over the years? You might be surprised by the rapid advancements that have taken place. In the early days, gearboxes were simple mechanical devices, primarily using gears to transmit power and torque. They relied on basic designs, which often limited efficiency and performance.

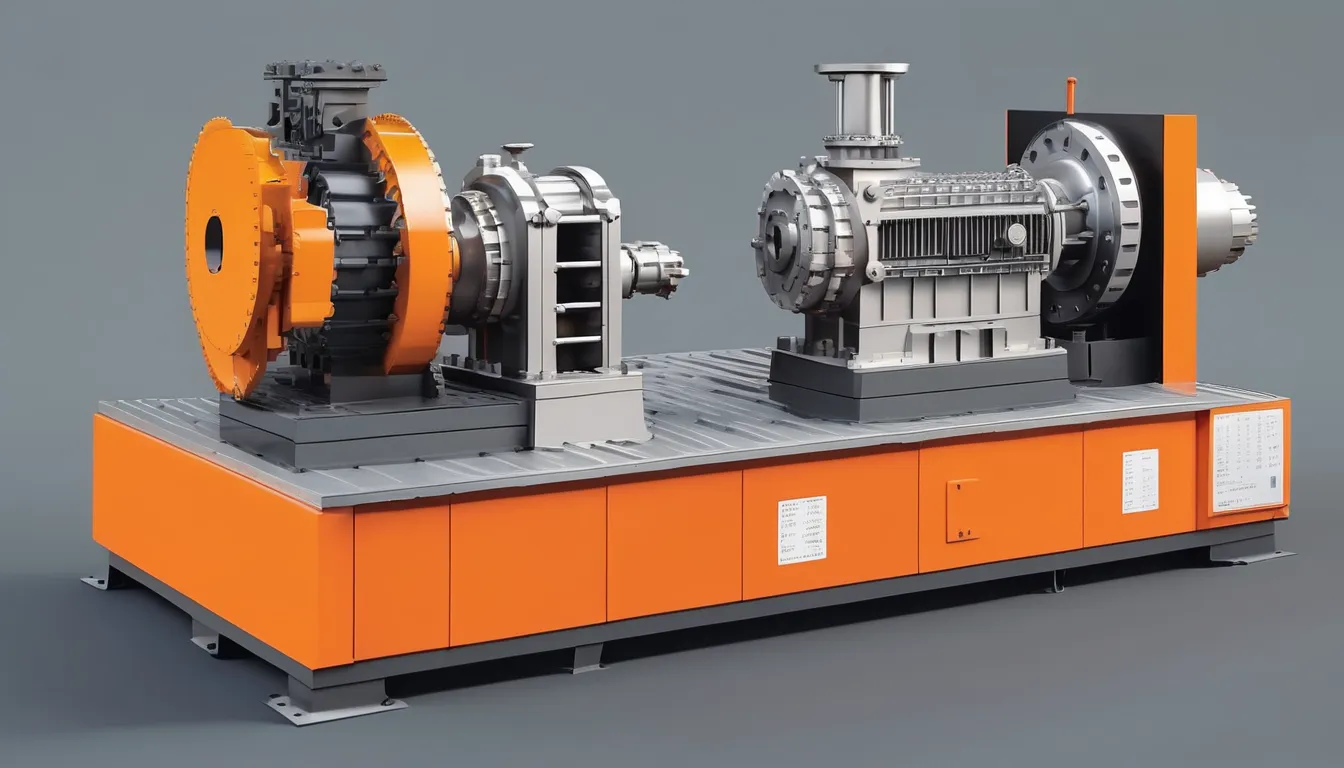

As technology evolved, engineers began to innovate, experimenting with materials and designs to improve reliability and capability. Fast forward to the 21st century, and you’ll see an impressive shift. Modern gearboxes utilize advanced materials like composites and lightweight metals, enhancing durability while reducing weight.

You’ll notice that computer-aided design (CAD) has revolutionized how gearboxes are built, allowing for precise calculations and simulations. This means you get more efficient designs that minimize energy loss during operation.

Additionally, the integration of smart technologies and sensors has marked a new era. These innovations enable real-time monitoring of gearbox performance, making it easier to diagnose issues before they escalate.

As a result, you benefit from increased longevity and improved maintenance schedules. The evolution of Industrial Gear Drive technology is a testament to human ingenuity, continuously pushing the boundaries of what’s possible in mechanical engineering.

Advantages of Modern Gearbox Designs

Modern gearbox designs offer a host of advantages that enhance performance and reliability. When you switch to these contemporary systems, you’ll notice significant improvements in efficiency, durability, and adaptability.

Here are three key benefits you can expect:

- Increased Efficiency: Modern gearboxes are engineered to minimize energy loss, allowing for smoother operation and reduced fuel consumption. This means you’ll save money in the long run while getting better performance.

- Enhanced Durability: With advanced materials and manufacturing processes, today’s gearboxes are built to withstand harsh conditions. This durability translates into longer service lives, reducing the need for frequent repairs and replacements.

- Greater Flexibility: Contemporary designs can be tailored to fit a variety of applications, from automotive to industrial machinery. This adaptability means you can optimize performance for specific needs, ensuring that your system runs at its best.

Key Innovations in Gearbox Engineering

Revolutionary advancements in gearbox engineering are transforming the way machinery operates. You might be surprised at how these innovations enhance performance and efficiency.

One key development is the integration of advanced materials, like composites and lightweight alloys, which reduce weight without compromising strength. This means you get more power with less energy consumption.

Another significant innovation is the implementation of modular designs. These allow for easier customization and maintenance, so you can adapt gearboxes to different applications quickly.

You’ll also appreciate the rise of smart gearboxes that incorporate sensors and IoT technology, providing real-time data on performance and wear. This leads to predictive maintenance, reducing downtime and extending the lifespan of your machinery.

Additionally, advancements in gear tooth design, such as hypoid and helical gears, minimize friction and noise, improving overall efficiency.

And let’s not forget about 3D printing, which enables rapid prototyping and production of complex gearbox components.

With these key innovations, you’re not just looking at improved machinery; you’re witnessing a shift towards more sustainable, efficient, and adaptable systems that meet the demands of modern engineering challenges.

Applications in Electric Vehicles

In recent years, the application of innovative gearbox designs in electric vehicles (EVs) has reshaped the industry.

These advancements focus on enhancing efficiency, reducing weight, and improving overall performance. By integrating cutting-edge technology, manufacturers are able to create gearboxes that cater specifically to the unique needs of electric propulsion systems.

Here are three key applications of these designs in EVs:

- Single-Speed Gearboxes: Many electric vehicles utilize single-speed gearboxes, simplifying the drivetrain and reducing complexity while maintaining effective torque delivery.

- Multi-Speed Transmissions: Some EVs are now equipped with multi-speed transmissions, allowing for optimized performance at various speeds, which enhances acceleration and efficiency during highway driving.

- Compact Designs: Innovative gearbox designs often prioritize compactness, allowing them to fit into smaller spaces within the vehicle, which leads to improved aerodynamics and overall vehicle design.

Future Trends in Gearbox Development

As the automotive industry moves forward, emerging trends in gearbox development promise to enhance performance and sustainability in electric vehicles.

You’ll notice a shift towards multi-speed gearboxes designed to optimize efficiency and power delivery. These systems allow for smoother acceleration and improved range, addressing one of the main concerns of EV users.

Another exciting trend is the integration of advanced materials like carbon fiber and lightweight alloys. By reducing weight, you can significantly enhance the overall efficiency of your vehicle, making it not just faster but also more energy-efficient.

Moreover, manufacturers are increasingly adopting modular designs. This flexibility allows for easier upgrades and maintenance, ensuring that your gearbox can adapt to new technologies as they emerge.

Finally, don’t overlook the rise of smart gearboxes with integrated sensors and AI capabilities. These intelligent systems can analyze driving patterns and adjust performance in real-time, optimizing your driving experience while conserving energy.

In essence, the future of gearbox development is all about enhancing efficiency, reducing weight, and improving adaptability.

You’ll want to keep an eye on these trends as they unfold, shaping the next generation of electric vehicles.

Conclusion

As you explore the innovative gearbox designs of the 21st century, you’ll see how they revolutionize efficiency and adaptability. With cutting-edge materials and smart technologies, these gearboxes not only enhance performance but also cater to the evolving demands of electric vehicles. Embracing advancements like IoT and advanced gear tooth designs, the future of gearbox engineering looks bright. Stay tuned for the exciting developments ahead, as they’ll shape the automotive landscape in ways you won’t want to miss!